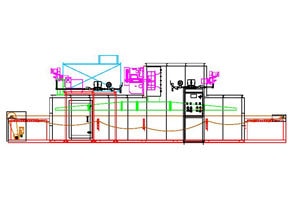

A manufacturer of custom ceramics came to Mahan Oven & Engineering Co., Inc in need of a custom belt oven with a thermal oxidizer. We designed and manufactured an oven with a 60-inch-wide stainless mesh belt and a 22-feet-long heated zone to dry their product completely. The oven had a maximum temperature of 350F. We worked closely with the client from start to finish, on all details of the custom project. There were a number of special features in the structure, exhaust, conveyor, and heating source aspects of the custom oven. These included a 4-inch thick interlocking panel exterior, an insulated door, a 304 stainless steel belt, and much more.

The customer was highly satisfied with our service, expertise, and over 40 years of experience that led to an outstanding product. For more information about this project, or to learn more about our other products and services, please contact Mahan Oven.

Specifications about this custom designed and manufactured belt oven

- Product Description

-

Continuous belt dryer with thermal oxidizer for ceramic parts

- Overall Oven Dimensions

-

Length: 33′ 5-3/4″

Width: 6′ 8″

Height: 10′

- Oven Features

-

Heating Source

- Maxon Gas Burner

- Honeywell Gas Valve Train

- Honeywell Flame Safeguard

- Backward Inclined Circulation Fan

- 350F Max. Temperature Structure

- Steel Support Frame

- 4″ Thick Interlock Exterior Panel

- Discharge Ductwork to Impinge Downward on Product and Belt

- Insulated Floor

- Access Doors Located on Main Oven Body and Heat Chamber

Exhaust

- Exhaust Fans w/ 1HP Motor Conveyor

- Cambridge MTR-12 60″ Width

- 304 Stainless Steel Belt

- Carbon Steel Herringbone Slider Bed

- Adjustable Speed AC Drive and Worm Gear Reducer